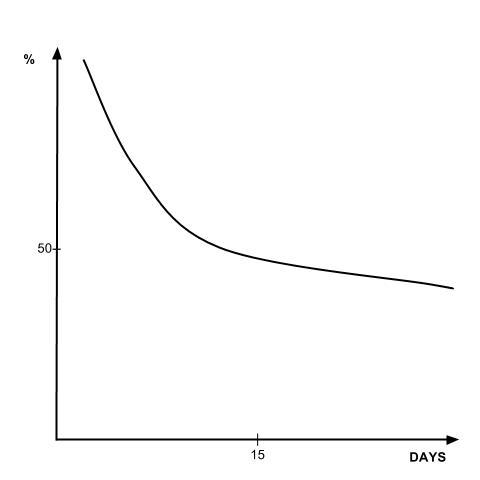

This chart, sourced from “Espresso Coffee: The Chemistry of Quality,” tracks the “degassing” of roasted coffee beans. The term degassing refers to the release of the carbon dioxide that forms during the roasting process and becomes trapped in the beans.

The above chart shows the decline in carbon dioxide during the thirty days following roast. Note the rapid drop during the first few days followed by more gradual reduction. It often takes weeks, if not months, to completely remove the carbon dioxide.

If you’re a cafe owner/manager, why should you care about degassing?

1. Coffee Beans Can Be Too Fresh: A massive amount of degassing occurs during the initial days following a roast. The outflow of carbon dioxide is rapid enough that it will interfere with the extraction process. As a result, you’ll find it difficult to produce high quality coffee or espresso until the beans have had enough time to rest (typically 3-5 days).

With our own Malabar Gold Espresso, for instance, we roast the beans on Monday but won’t use them until Friday or Saturday (i.e. five day wait). And if you’ve ever tried Malabar Gold at a coffee or food show, the beans we used there would have been roasted TWO MONDAYS before (i.e. a 10-14 day wait).

2. Inventory Management Becomes an Important Skill: Not restocking until you run low on coffee beans will hurt your cafe’s ability to serve high quality coffee and espresso. Because rapid degassing will occur for 3-5 days following roast, you will need to order new beans 4-6 days before you need/can use them. This will require owners and managers to have a good grasp on their cafe’s daily/weekly consumption of beans. Placing orders with your roaster on a regular schedule (i.e. weekly or twice weekly) is often the best system for ensuring that your cafe isn’t using beans that are too fresh.

Want to Learn More about Coffee and Espresso? Visit the Educational Resources section of our website.